Planning for SAP in 2026: A Practical AI Playbook for S/4HANA and ECC Customers

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

.png)

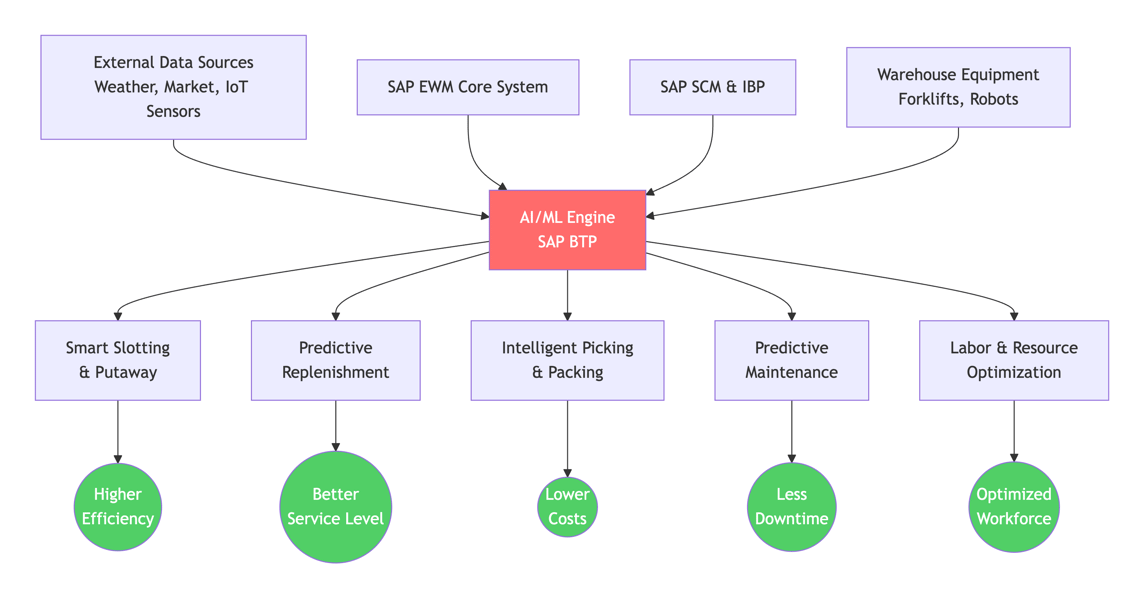

In today's fast-paced, omni-channel world, the warehouse is no longer just a storage facility. It’s the dynamic, beating heart of the supply chain. Customers expect faster delivery, complete visibility, and perfect order accuracy. Meanwhile, operations teams face labor shortages, rising costs, and an overwhelming volume of data.

Traditional Warehouse Management Systems (WMS) and automation solutions have served well, but primarily focus on execution and reporting. They tell you what happened but rarely explain why or predict what will happen next. To move forward, businesses need a system that learns, predicts, and prescribes, turning data into actionable intelligence.

Warehouses have evolved into high-speed distribution hubs that directly influence customer satisfaction. Even a slight delay can trigger significant ripple effects, increasing costs and eroding trust. Supervisors and operations managers must constantly balance workloads, maintain throughput, and ensure all shipments meet their deadlines.

This is where Artificial Intelligence (AI), powered by SAP Joule and embedded in SAP EWM, redefines warehouse management. By combining predictive analytics, AI-based decision-making, and conversational automation, operations can transition from reactive firefighting to proactive orchestration. This approach drives continuous optimization - predicting workload surges, reallocating resources efficiently, and maintaining performance with minimal manual input.

Before exploring the AI-driven transformation, it’s essential to understand the key challenges faced by conventional warehouse setups:

• Static Planning: Resource allocation is often based on fixed schedules or past averages, overlooking daily demand fluctuations.

• Limited Visibility: Supervisors rely on periodic reports that lack real-time insights into workload dynamics.

• Reactive Response: Issues are identified only after they affect operations, leaving little time for corrective action.

• Inefficient Utilization: Overstaffed zones coexist with understaffed ones, resulting in reduced productivity.

• Lack of Predictive Insight: Legacy systems show what’s happening but not what’s coming next.

AI addresses these limitations by continuously learning from operational data, recognizing patterns, and making predictive adjustments that keep performance optimized throughout the day.

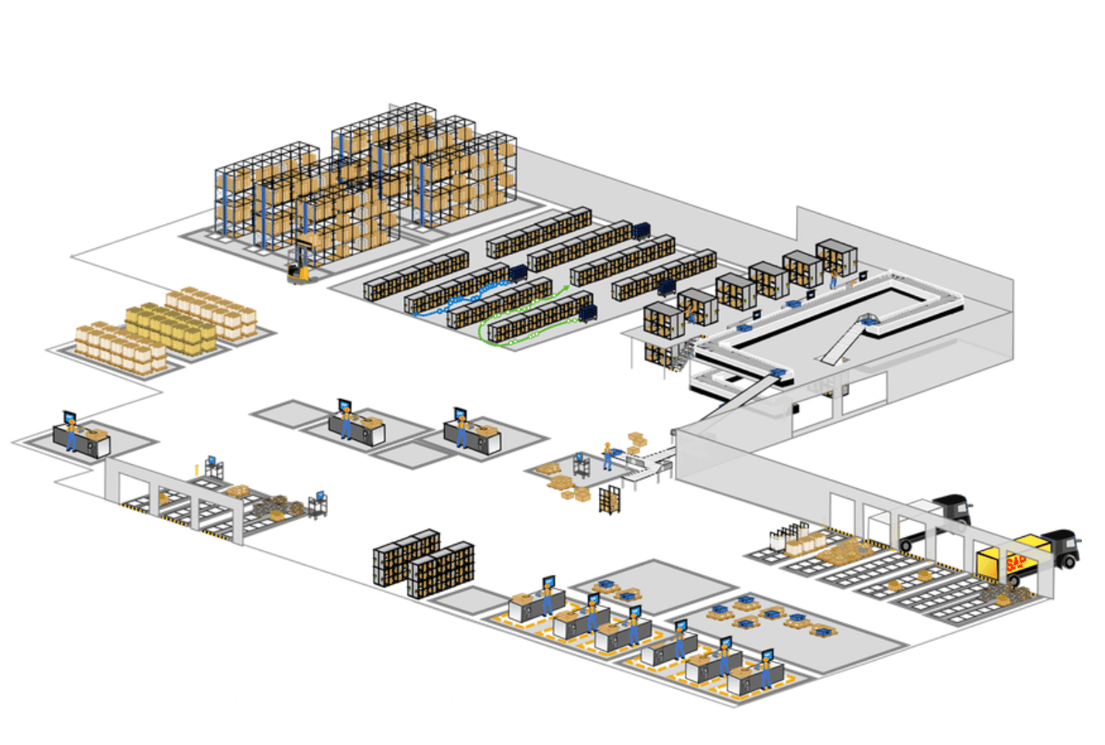

The AI-based Warehouse Workload Visibility Application represents the core of this transformation. It provides a unified, intelligent view of operations through predictive analytics and optimization algorithms.

Using embedded AI within SAP EWM, the system analyzes order volumes, resource capacity, and historical performance to forecast workload intensity for each area—picking, packing, staging, and shipping. This proactive insight helps managers foresee bottlenecks and address them before they cause delays.

A modern SAP UI5 dashboard clearly visualizes these insights. Managers can compare planned versus predicted workloads, spot high-risk areas, and simulate adjustments instantly. For example, if the packing area is forecasted to exceed capacity by 15%, the system recommends transferring personnel from a less active zone. Users can approve these recommendations or run manual simulations to test alternate plans.

When automatic rebalancing is activated, AI algorithms evaluate constraints such as skill sets, equipment compatibility, and zone permissions. Once an optimized plan is approved, SAP EWM APIs seamlessly execute the reassignments, ensuring that every resource receives an updated, balanced workload.

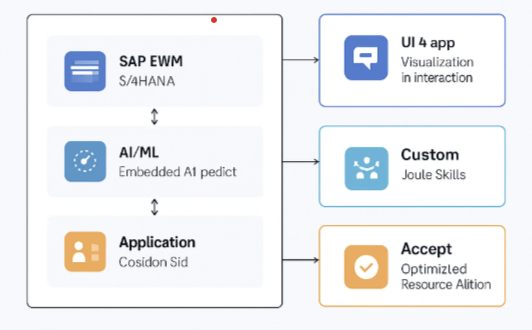

SAP Joule serves as an intelligent assistant, empowering managers through AI-driven conversational interaction. It enhances decision-making, automation, and operational transparency via three custom skills:

• Current Workload Analysis: Joule aggregates live data across activity areas, identifying dependencies such as delayed picking that may affect packing or shipping timelines.

• Provide Optimized Resource Allocation: This skill runs real-time AI simulations to suggest optimal workforce or machine distribution. It considers order priority, task complexity, and workload balance.

• Accept Optimized Resource Allocation: Once validated, Joule triggers automatic updates in SAP EWM, reassigning staff, equipment, or robots to the new configuration instantly.

Beyond analytics, Joule allows natural interaction. Managers can ask, “Joule, where are we at risk of missing today’s shipping goals?” or “Show me an optimized allocation for the afternoon surge.” The system responds with data-backed recommendations and can execute them upon approval. This fusion of human expertise and AI intelligence enables truly adaptive, self-optimizing operations.

Integrating AI and Joule into warehouse operations generates measurable improvements across multiple dimensions:

• Predictive Control: Detect potential disruptions before they impact performance.

• Optimized Workforce Utilization: Dynamically balance staff and automation based on real-time demand.

• Reduced Operational Costs: Minimize overtime and increase throughput, reducing cost per order.

• Improved SLA Compliance: Consistently achieve on-time deliveries, enhancing customer satisfaction.

• Data-Driven Decision-Making: Empower managers with real-time, AI-powered insights.

Over time, the system continuously learns from performance data, fine-tuning predictions and adapting to seasonal patterns. The result is a self-optimizing warehouse ecosystem that aligns resources dynamically with business objectives.

Future advancements may include:

• Integration with IoT sensors for live equipment monitoring.

• Digital Twin simulations to visualize process improvements before implementation.

• Autonomous robotics coordination guided by AI forecasting.

• Energy optimization for sustainability and reduced costs.

In essence, SAP EWM and SAP Joule usher in a new era of intelligent warehousing - where systems don’t just report performance but enhance it. By embracing AI-powered optimization, companies evolve from reactive management to predictive excellence, achieving agility, cost efficiency, and superior service.

The fusion of AI, analytics, and automation through SAP Joule transforms warehouses into intelligent command centers. It’s not just about achieving today’s targets; it’s about building a predictive, proactive foundation for tomorrow’s operational excellence.

.png)

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

.png)

2026 has made one thing unmistakably clear: AI is no longer knocking on the door - it’s already running the building. Across industries, SAP leaders...

.png)

From my seat – inside deals, renewals, and delivery conversations every week – the story from early 2025 to early 2026 is simple: last year’s...

.png)

4 min read

.png)

6 min read

Read More

Read More