Planning for SAP in 2026: A Practical AI Playbook for S/4HANA and ECC Customers

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

3 min read

Deepali Shukla

:

Mar 10, 2025 9:48:09 AM

Deepali Shukla

:

Mar 10, 2025 9:48:09 AM

EWM-PP integration and various consumption options in S/4HANA with SAP Public/ Private Cloud / On-Premises

In today’s fast-paced manufacturing environment, efficient integration between different business processes is crucial for streamlining operations, improving accuracy, and reducing costs. One such vital integration is the seamless coordination between SAP Extended Warehouse Management (EWM) and Production Planning (PP). These two SAP modules work together to ensure that production is well-supported by timely materials handling and that goods flow seamlessly from the warehouse to production lines and back.

Let’s dive into how the EWM PP process works and how businesses can optimize this integration to enhance productivity and accuracy.

1. Overview of EWM and PP Integration

SAP EWM is an advanced warehouse management system designed to manage the complex movements of materials within warehouses. It allows for optimized material handling, tracking, and inventory management across different locations in real time.

On the other hand, SAP PP focuses on managing production planning and execution. This module handles the production process, from order creation to material consumption and tracking the status of production orders.

When integrated, EWM and PP help to ensure that production orders are well-supported by timely material availability and efficient warehouse operations. This integration leads to:

2. The Role of Backflush in the EWM PP Process

A key aspect of the integration between EWM and PP is the backflush process. Backflushing is the automatic posting of material consumption in SAP based on production activities. This method is efficient and helps reduce manual data entry, ensuring that materials are consumed as they are used in the production process.

In SAP EWM, when a material is marked as a backflush item in the manufacturing order, the system will not allow manual goods issue entry in the warehouse. Instead, the system automatically posts the goods issue once the production order is confirmed in SAP (ERP) S/4 Hana , which triggers the creation of a synchronous warehouse task in EWM for the material’s movement.

This ensures that there is no discrepancy between the inventory in the warehouse and the materials consumed during production, thereby reducing errors and improving inventory accuracy.

3. Staging of Components

Material staging is a critical component of the EWM PP process, as it ensures that the right materials are available at the production line when needed.

In the traditional EWM PP process:

Materials are staged before production begins. This involves physically moving materials from the warehouse to a staging area close to the production line.

Staging is necessary for components that are not set as backflush items. These materials need to be manually issued and staged before consumption.

For backflush materials, the consumption is automatically triggered during the production confirmation, reducing the need for manual intervention and improving production efficiency.

Staging also involves monitoring stock levels in real time, allowing for more effective inventory management. Using RF (Radio Frequency) or Fiori Apps, workers can quickly and accurately confirm goods movements and consumption, reducing errors and improving operational speed.

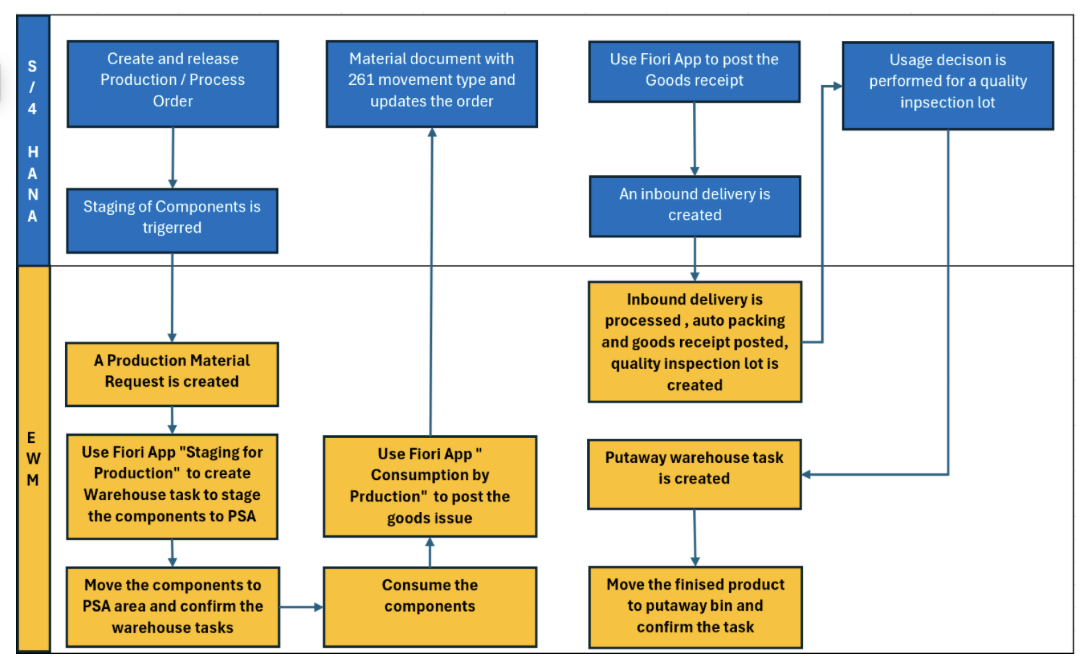

Note: Refer to the Flow Chart for the Process flow

4. Goods Issue and Post Consumption

The goods issue process is fundamental to tracking material consumption in production. SAP EWM allows goods issues to be processed either through RF devices or the Fiori App, giving flexibility and real-time updates to workers on the warehouse floor.

Fiori App “Consumption by Production”

Fiori RF Path

Here’s how the goods issue typically works:

In both scenarios, the system ensures accurate tracking of materials, reducing errors related to stock levels, production planning, and consumption.

5. The Benefits of Optimizing the EWM PP Process

Optimizing the integration between EWM and PP offers significant advantages for businesses, including:

6. Challenges in the EWM PP Process and How to Overcome Them

While the integration of EWM and PP offers several advantages, some challenges can arise, including:

Conclusion

The EWM PP process is a powerful tool for optimizing warehouse and production operations, reducing manual intervention, and ensuring material availability. By streamlining processes such as backflushing, staging, goods issue, and post-consumption tracking, businesses can create a more efficient and accurate supply chain, ultimately improving their bottom line.

By ensuring that SAP EWM and PP work seamlessly together, manufacturers can achieve higher productivity, better inventory management, and improved overall operational efficiency.

.png)

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

.png)

2026 has made one thing unmistakably clear: AI is no longer knocking on the door - it’s already running the building. Across industries, SAP leaders...

.png)

From my seat – inside deals, renewals, and delivery conversations every week – the story from early 2025 to early 2026 is simple: last year’s...

-1.png)

1 min read

SAP Fleet Management (SAP FM) is not a built-in component of SAP S/4HANA. However, SAP FM can be integrated with SAP S/4HANA to provide a...

5 min read

5 min read