Planning for SAP in 2026: A Practical AI Playbook for S/4HANA and ECC Customers

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

3 min read

Navin Chaubey

:

Jun 19, 2025 11:13:50 AM

Navin Chaubey

:

Jun 19, 2025 11:13:50 AM

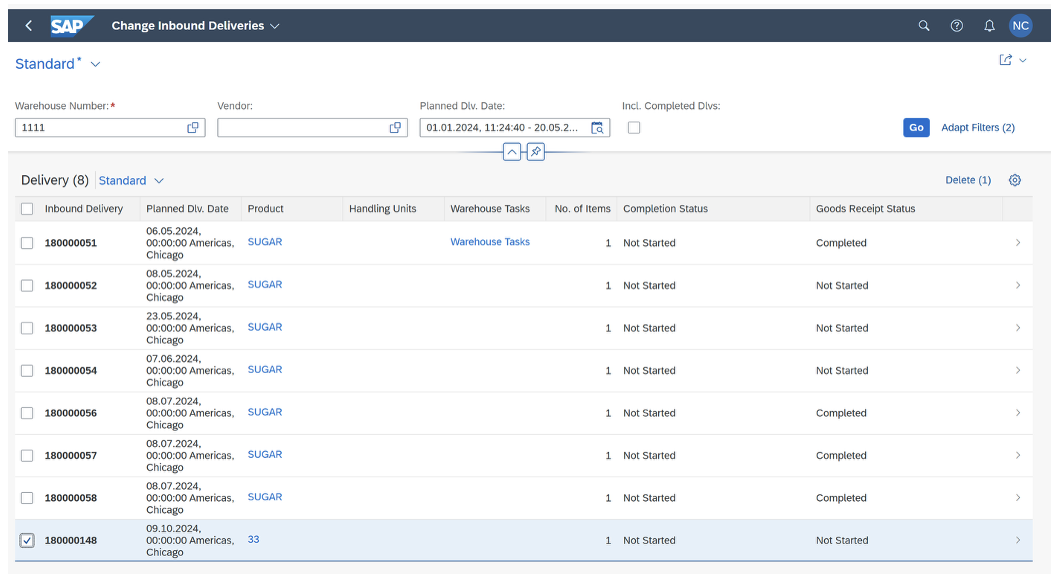

In modern warehouse operations, speed, accuracy, and flexibility are non-negotiable. For businesses using SAP Extended Warehouse Management (EWM), managing inbound deliveries efficiently can be the key to seamless operations. One tool that significantly enhances this process is the Change Inbound Delivery app. This Fiori-based application empowers users to manage and update delivery data in real time, improving accuracy and reducing operational delays. Here are the top advantages of using this app in your EWM environment.

Mistakes in delivery data can happen due to supplier errors, manual entry, or last-minute changes. Traditionally, correcting this data in SAP requires backend involvement or reprocessing the entire delivery. With the Change Inbound Delivery app, users can quickly correct information like delivery quantities, packaging details, or dates directly through an intuitive interface. This saves time and minimizes disruption.

Fiori App

Display a list of open inbound deliveries

Easy Packing

Built on the SAP Fiori framework, the app provides a modern and clean user experience. The intuitive layout and design make it accessible even to users who are not SAP experts. This improves user adoption, reduces training costs, and empowers warehouse staff to take direct action without waiting on IT support.

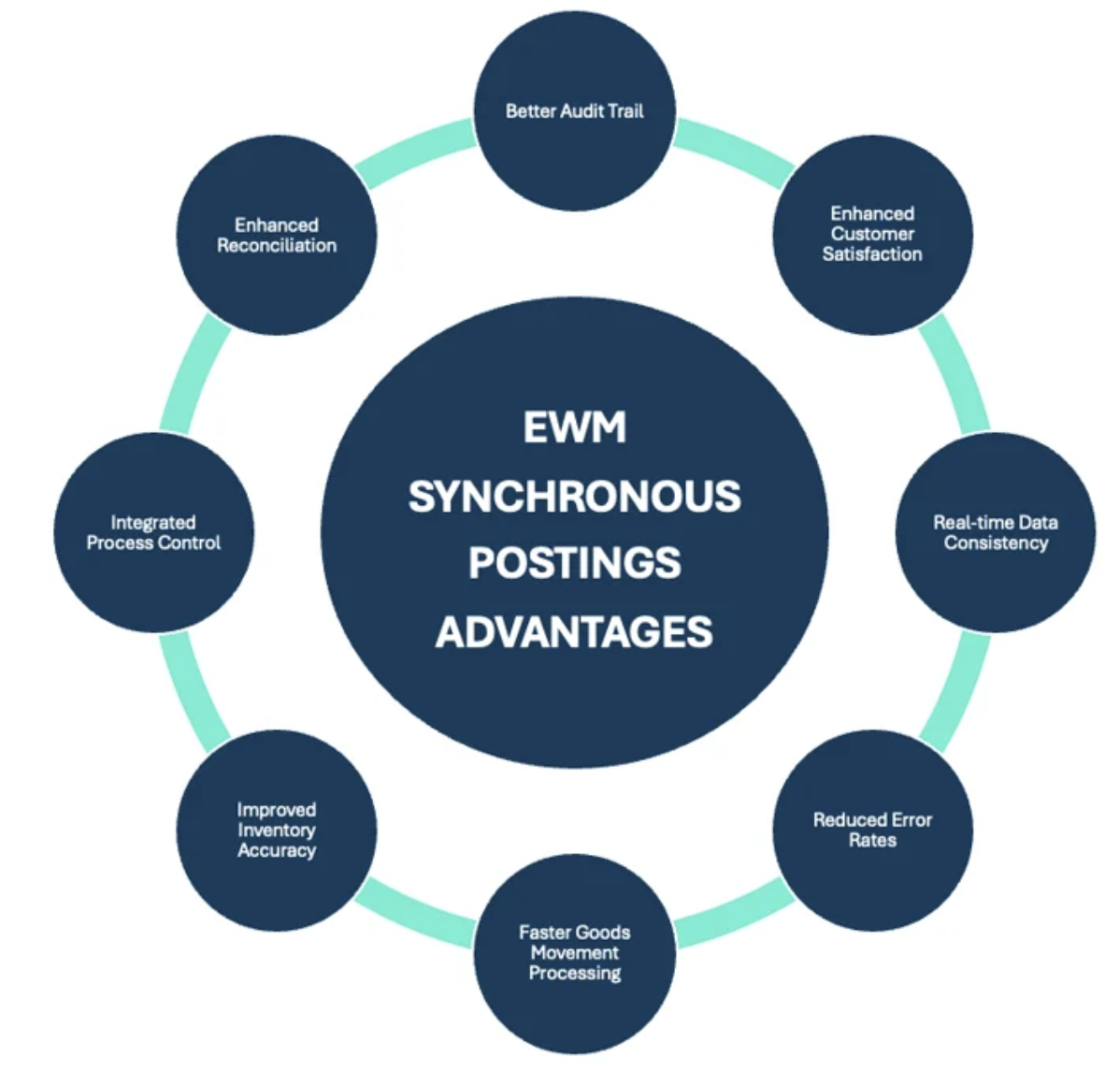

When changes are made using the app, they are immediately reflected in the EWM system. This ensures that warehouse activities such as goods receipt, quality inspections, and putaway are executed based on the most accurate and up-to-date information. Real-time visibility eliminates delays and enhances decision-making.

Supply chain operations are dynamic, and flexibility is essential. The app supports modifications to key delivery attributes without needing to cancel or recreate documents. Whether it’s adjusting the delivery time or updating product quantities, users can make changes on the fly, enabling warehouses to adapt quickly to unexpected changes.

In a warehouse management system, tasks can be created manually or through straightforward rule-based methods. Warehouse task creation without strategy options refers to a basic approach where the destination bins, as well as the timing and assignment of the tasks, are predefined or manually entered.

This method is typically used in less complex warehouse environments where operations are predictable and consistent. In this setup, the system follows fixed rules or user inputs for selecting bins and creating warehouse tasks.

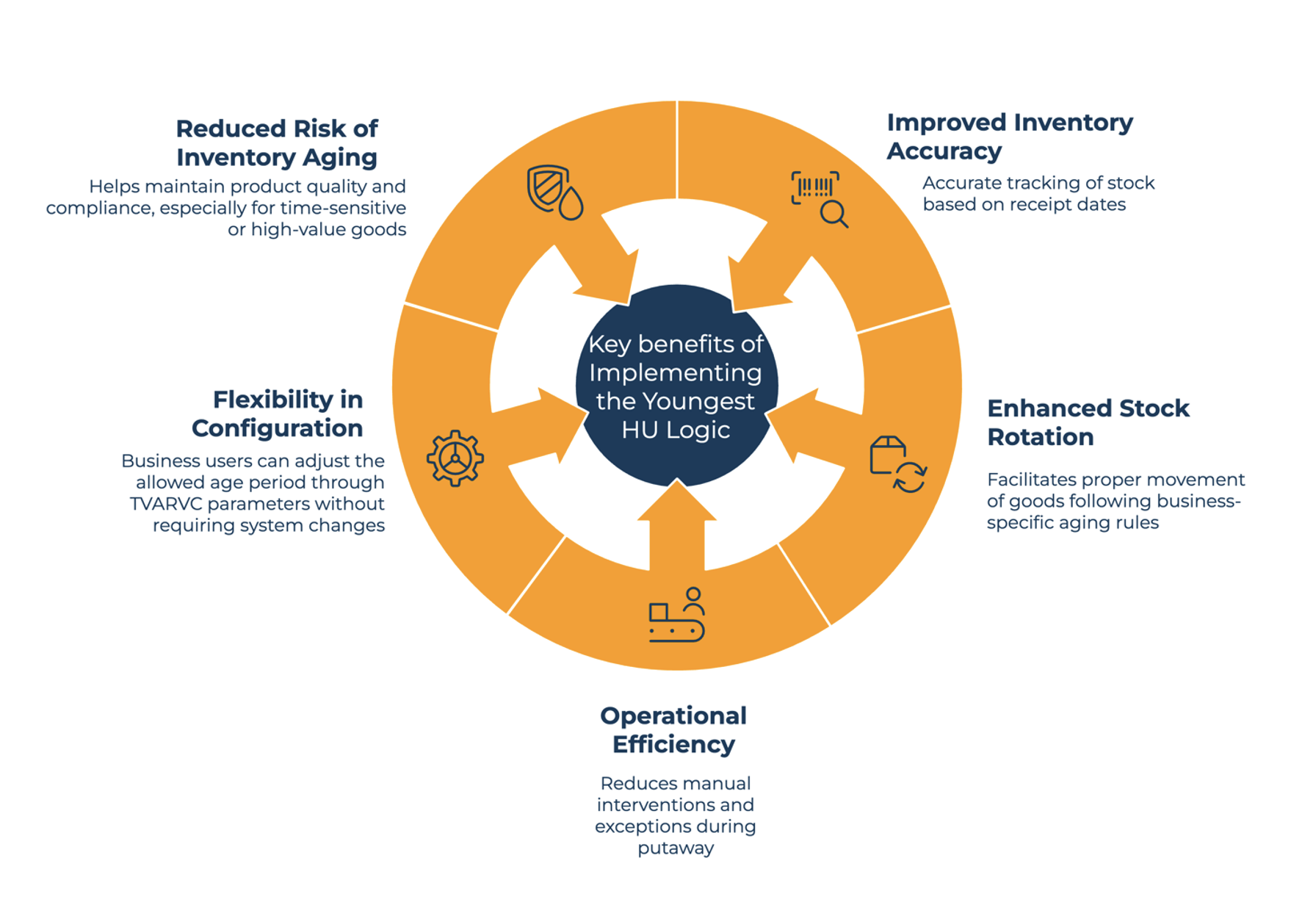

Modern warehouse management systems support task creation using strategy options, which enable dynamic, rule-based decision-making during task creation. Strategies such as putaway are configured based on parameters like stock type, storage section, batch, expiry date, and warehouse zone. These strategies help automate the decision on where to put stock to, as well as when and how tasks should be performed.

Using strategy options significantly increases the efficiency of warehouse operations by minimizing travel time, balancing workloads, and ensuring better stock rotation. The system selects the optimal destination bins and may also assign the task to the most suitable resource (worker or equipment).

Warehouse task confirmation is a critical step in warehouse operations, ensuring that movements such as picking, putaway, and stock transfers are accurately recorded in the system. With the introduction of SAP Fiori apps, this process has become more efficient, user-friendly, and mobile.

In SAP Extended Warehouse Management (EWM), warehouse tasks represent the physical movement of goods. Task confirmation is the action of verifying and completing those tasks in the system once the physical movement is done.

The Fiori app for warehouse task confirmation provides a modern, role-based interface that allows warehouse workers to confirm tasks directly from the tablets or desktops. It replaces the need for traditional SAP GUI transactions or paper-based confirmations.

By providing a streamlined and standardized method for updating delivery data, the app helps reduce the likelihood of errors that can lead to inventory discrepancies, compliance issues, or customer dissatisfaction. Ensuring data integrity also helps maintain audit trails and adhere to regulatory requirements.

Manual workarounds and back-and-forth communication with other departments slow down warehouse operations. With the Change Inbound Delivery app, employees can resolve issues on the spot. This accelerates inbound processing and increases productivity across the warehouse.

The app doesn’t work in isolation. It integrates smoothly with SAP modules such as Materials Management (MM), Transportation Management (TM), and Quality Management (QM). This connectivity ensures that changes made to delivery data are automatically aligned across related processes.

The Change Inbound Delivery app for SAP EWM is more than just a convenience—it’s a strategic tool for optimizing warehouse efficiency. By enabling real-time, user-friendly updates to inbound deliveries, it supports a responsive and accurate logistics process. If your organization is looking to improve operational agility, reduce errors, and enhance visibility, this app is well worth considering.

Ready to see it in action? Contact us to schedule a demo.

.png)

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

.png)

2026 has made one thing unmistakably clear: AI is no longer knocking on the door - it’s already running the building. Across industries, SAP leaders...

.png)

From my seat – inside deals, renewals, and delivery conversations every week – the story from early 2025 to early 2026 is simple: last year’s...

11 min read

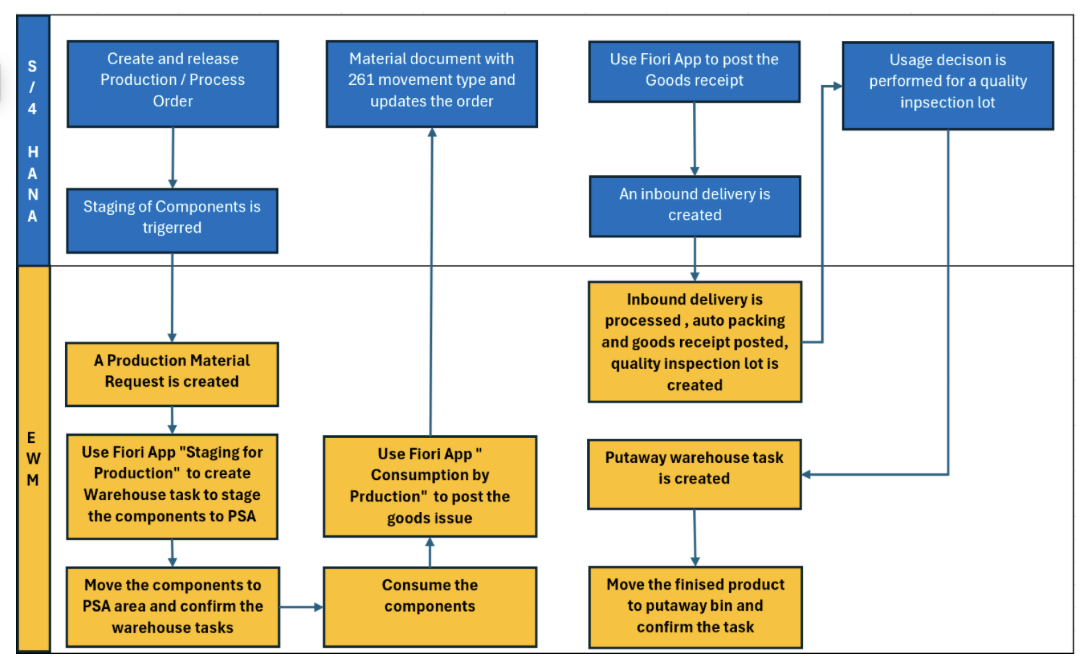

EWM-PP integration and various consumption options in S/4HANA with SAP Public/ Private Cloud / On-Premises

5 min read

3 min read