Planning for SAP in 2026: A Practical AI Playbook for S/4HANA and ECC Customers

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

4 min read

Sohit Reddy

:

May 1, 2025 2:57:40 PM

Sohit Reddy

:

May 1, 2025 2:57:40 PM

As the global automotive industry continues to evolve amidst unprecedented disruption, supply chain efficiency has emerged as a critical differentiator for tier-one suppliers. Within this context, License Plate Management (LPM) has become a transformative technology enabling real-time visibility, enhanced traceability, and streamlined warehousing operations. At Mygo Consulting, we're witnessing firsthand how advanced license plate management is revolutionizing automotive supply chains. This comprehensive blog series explores the multifaceted applications of LPM technology within SAP Extended Warehouse Management (EWM) for tier-one automotive suppliers, with actionable insights for implementation and optimization.

License Plate Numbers (LPNs) have evolved from basic ID tags to smart identifiers for handling units like pallets, containers, and cartons in SAP Extended Warehouse Management (SAP EWM). They form the backbone of end-to-end traceability in today’s automotive supply chains.

As the industry shifts toward more complex manufacturing—balancing internal combustion and electric vehicles—the need for flexible, real-time tracking has grown. Unlike outdated paper-based systems or manual barcode scanning, modern LPM systems in SAP EWM support dynamic, automated material flows that align with just-in-time (JIT) production. This shift reflects the broader digital transformation happening across the automotive value chain.

For tier-one automotive suppliers, license plate management (LPM) has become essential. With growing complexity in EV and hybrid components, rising OEM expectations, and stricter global traceability regulations, suppliers need robust tracking systems more than ever.

Implemented in SAP EWM, LPM provides a digital framework for tracking handling units from goods receipt to putaway, picking, and shipping. It’s especially valuable for managing complex assemblies where individual sub-components must be tracked for quality control and compliance.

Imagine scanning one label and tracking thousands of components instantly. Within SAP EWM, license plates function as logical containers that aggregate multiple material items into a single tracking entity. The architecture consists of several key components: unique license plate identifiers, handling unit management functionality, and integration with RF (Radio Frequency) scanning devices. This architecture enables warehouse personnel to track multiple materials simultaneously through a single scan, dramatically improving operational efficiency.

The license plate data model in SAP EWM maintains hierarchical relationships between handling units, allowing for nested structures such as pallets containing multiple cartons, each with their own license plate. This hierarchical model enables granular tracking while maintaining operational simplicity - warehouse associates need only scan the parent license plate to capture data about all contained items. For automotive suppliers managing thousands of distinct components, this capability transforms warehouse operations by reducing scanning time while enhancing data accuracy.

License Plate Numbers are linked to the internal HU number range through the HU identification and ID Type in the HU Number Assignment settings.

ID type defines the method of identification. Multiple ID types can be configured to distinguish between internal and external HUs as per customer-specific requirements.

1. Hierarchical Handling Unit Model: SAP EWM supports a hierarchical HU structure, meaning one LPN (parent) can encapsulate multiple nested HUs (child). For example, a pallet might contain several cartons, each with its own LPN. Scanning the parent LPN gives visibility into the entire structure, dramatically reducing scanning effort while improving data accuracy and traceability.

2. Vendor Receiving: During inbound receiving, warehouse associates can capture supplier-provided LPNs using custom RFUI screens. These screens allow users to scan and register the LPNs against inbound deliveries. The system uses external ID types (like 02 or 04) to validate and record the LPNs, which ensures consistency between vendor documentation and warehouse data, streamlining goods receipt and inventory tracking.

3. Truck Check-In: LPN capture can occur as early as the truck arrival at the gate. Using custom RF screens, LPNs from shipping labels or packing slips are scanned and linked to expected deliveries.

This early registration allows for pre-allocation of putaway tasks, faster staging, and better yard management. The scanned LPNs also serve as a basis for real-time visibility and improved dock scheduling.

4. Internal Warehouse Movements: Once HUs are identified and LPNs assigned, warehouse operations like putaway, picking, repacking, and consolidation revolve around the LPN. Scanning a single LPN lets warehouse workers complete tasks without needing to manually scan each item or sub-unit, speeding up transactions while ensuring accuracy. Internal LPNs can be generated using system-defined number ranges and tied to specific ID types.

5. Cycle Counting & Inventory Accuracy: Cycle counting becomes faster and more accurate when performed at the LPN level. Scanning an LPN provides immediate access to the quantities and batch details inside the HU, enabling warehouse teams to validate inventory without having to open cartons or pallets unless necessary. This improves counting speed and reduces operational disruptions.

6. Outbound Processing & ASN Generation: During outbound processes, LPNs are verified or newly assigned at packing stations. They are used to print SSCC labels and included in Advanced Shipping Notifications (ASNs) for customers. Using the correct LPN format ensures compliance with customer requirements, streamlining integration and preventing delivery rejections.

7. Custom RFUI Screens for Flexibility: To support complex processes, many organizations implement custom RFUI screens to automate LPN capture, assign appropriate ID types, validate vendor-provided LPNs, and handle unique business rules. These custom screens enhance usability for warehouse associates and embed logic that ensures data integrity across all process steps.

For high-volume automotive warehouses, license plate scanning via RF devices is a game-changer. It delivers real-time tracking of every part and component, enabling faster workflows and complete traceability across the warehouse floor.

How It Works:

- RF scanners (handheld or vehicle-mounted) connect directly to SAP EWM.

- Every scan instantly records LPN movements - no delays, no manual entry.

- Updates flow in real time across inventory, staging, and shipping processes.

Why It Matters for Automotive Suppliers:

- Immediate putaway confirmation ensures materials land in the right spot

- Improved picking accuracy means fewer errors, rework, or shipping delays

- Faster inventory reconciliation—no need to wait for cycle counts

- Built-in exception handling for damaged goods, partial quantities, or quality holds

.png)

2026 is closer than it appears, and for SAP customers, it must become the year of AI outcomes - not simply AI awareness, experimentation, or...

.png)

2026 has made one thing unmistakably clear: AI is no longer knocking on the door - it’s already running the building. Across industries, SAP leaders...

.png)

From my seat – inside deals, renewals, and delivery conversations every week – the story from early 2025 to early 2026 is simple: last year’s...

5 min read

11 min read

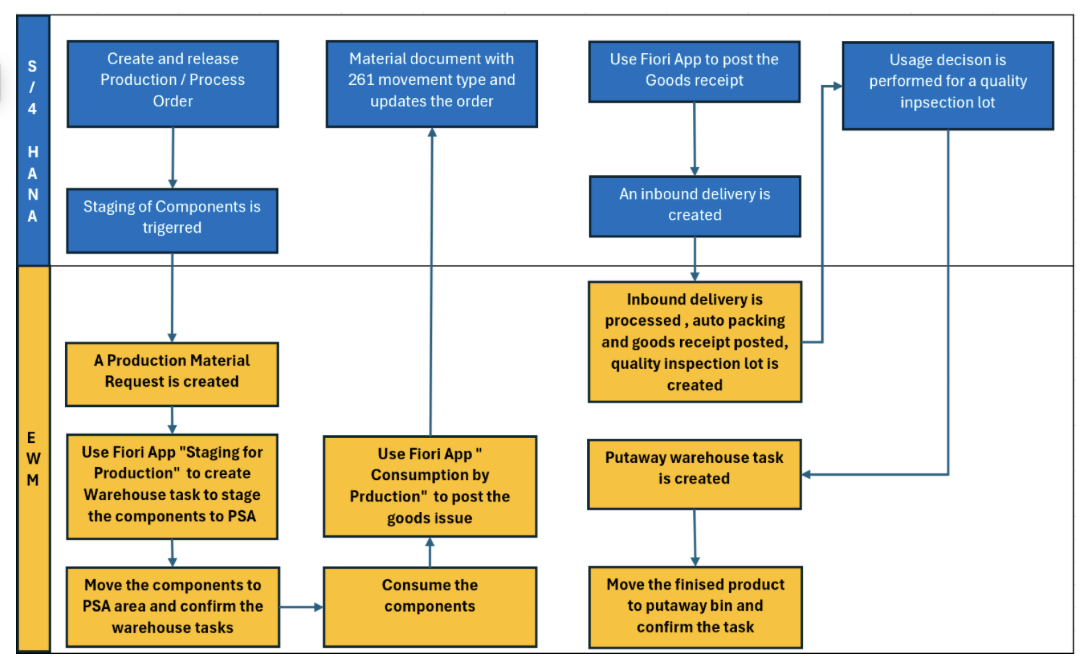

EWM-PP integration and various consumption options in S/4HANA with SAP Public/ Private Cloud / On-Premises

5 min read