Enterprise Software in 2026: AI Hype, SaaS Hangovers, and What Actually Matters Now

From my seat – inside deals, renewals, and delivery conversations every week – the story from early 2025 to early 2026 is simple: last year’s...

4 min read

Sohit Reddy

:

May 14, 2025 12:11:19 PM

Sohit Reddy

:

May 14, 2025 12:11:19 PM

The convergence of Internet of Things (IoT) technology with license plate management represents the cutting edge of warehouse automation for automotive suppliers. IoT sensors attached to handling units can continuously transmit data about location, temperature, shock/vibration, and other environmental factors directly to SAP EWM. This creates a dynamic digital twin of each handling unit, enabling proactive management of sensitive components and assemblies.

Advanced implementations incorporate RFID (Radio-Frequency Identification) technology to enable passive tracking of license plates throughout the warehouse without requiring manual scanning. Fixed RFID readers at strategic locations automatically record license plate movements, creating a comprehensive digital trail of component locations. This approach aligns perfectly with Industry 4.0 initiatives prevalent in the automotive sector, supporting transparency and efficiency in tracking critical parts.

This integration involves defining storage bin structures, establishing material flow rules for AGV operation areas, and configuring AGVs as resources within SAP EWM.

Through this integration, license plates become the communication mechanism between EWM and the AGV fleet management system.

The technical implementation typically leverages SAP Plant Connectivity to establish reliable communication protocols between EWM and AGV systems. Once implemented, this integration enables fully automated material movements directed by license plate identification. For example, an AGV can automatically retrieve a specific pallet based on its license plate, transport it to a picking station, and then return the pallet to storage - all orchestrated through SAP EWM's license plate management capabilities.

One of the most significant advancements in license plate management involves the elimination of internal label printing processes. Leading automotive suppliers are implementing systems where no labels are printed or triggered internally - instead, all tracking is managed through vendor labels and license plates. This approach eliminates redundant labeling, minimizes human error, and streamlines inbound processing for greater operational efficiency.

The implementation requires close collaboration with suppliers to standardize label formats and ensure consistent license plate information across the supply network. SAP EWM can be configured to recognize and process these vendor-supplied license plates automatically upon receipt, eliminating the need for relabeling while maintaining complete traceability. For tier-one suppliers processing thousands of incoming shipments daily, this capability dramatically reduces handling time while improving data accuracy.

License Plate Management (LPM) plays a critical role in enabling just-in-time cross-docking for time-sensitive automotive components.

By scanning LPNs at receiving, SAP EWM can instantly determine whether materials should be stored or bypassed and sent directly to outbound shipping.

Why It Matters:

• Reduces storage needs

• Speeds up material flow

• Ensures timely delivery to assembly lines

• Supports lean manufacturing with limited line-side space

How It Works:

• SAP EWM compares incoming LPNs with open production orders or shipping demands

• When there's a match, the system triggers real-time flow instructions

• Handling units are routed directly to cross-docking zones, bypassing storage

The concept of digital twins has gained significant traction in the automotive industry, and license plate management serves as a foundational element for implementing this technology in warehouse operations. Each license plate effectively becomes a digital representation of physical handling units, enabling real-time tracking, status monitoring, and predictive analytics. This approach aligns with broader digital transformation initiatives across the automotive supply chain.

The implementation involves integrating SAP EWM with the SAP Digital Vehicle Hub, creating a comprehensive digital representation of components from the warehouse to final vehicle assembly. This integration enables consistent information flow throughout the component lifecycle, enhancing both operational efficiency and quality assurance capabilities. For tier-one suppliers, this digital continuity provides unprecedented visibility into component journeys from warehouse to finished vehicle.

License plate management generates rich data streams that can be leveraged for advanced analytics and business intelligence. By analyzing license plate movement patterns, dwell times, and handling exceptions, automotive suppliers can identify warehouse optimization opportunities and predict potential bottlenecks before they impact operations. This capability transforms license plate data from operational information into strategic intelligence.

The integration of SAP EWM with SAP Analytics Cloud enables sophisticated visualization and analysis of license plate data, supporting data-driven decision making across warehouse operations. Dashboards can be customized to highlight key performance indicators such as license plate processing time, handling exceptions, and cross-docking efficiency.

For operations executives, these insights enable continuous improvement initiatives based on concrete operational data rather than anecdotal observations.

As SAP Warehouse Management (WM) approaches its end of support by 2025, tier-one automotive suppliers must prioritize migration to SAP Extended Warehouse Management (EWM) to maintain operational continuity and competitive advantage. This migration presents an ideal opportunity to implement advanced license plate management capabilities that weren't available in legacy WM systems.

The migration strategy typically involves a phased approach beginning with a comprehensive assessment of existing warehouse processes, pain points, and business objectives. The transition plan includes mapping current WM functionalities to EWM capabilities, ensuring stakeholder alignment, and developing a seamless inventory data migration strategy. For automotive suppliers with global operations, leveraging expertise from experienced SAP implementation partners like Mygo Consulting ensures a successful migration with minimal operational disruption.

Successful implementation of license plate management requires comprehensive change management and training programs to ensure warehouse personnel fully embrace the new technology. The structured training approach should include workshops, hands-on sessions, and continuous support to build confidence and proficiency with license plate scanning devices and associated processes.

Particularly important is helping warehouse staff understand the end-to-end implications of license plate management—how their scanning activities contribute to broader supply chain visibility and manufacturing efficiency. For tier-one automotive suppliers with multiple facilities, developing standardized training materials and implementation playbooks ensures consistent adoption across the organization while accommodating site-specific requirements.

License plate management within SAP EWM represents a transformative technology for tier-one automotive suppliers navigating an increasingly complex manufacturing landscape. By implementing advanced license plate capabilities, suppliers can achieve enhanced operational efficiency, improved traceability, and seamless integration with broader Industry 4.0 initiatives. The technology serves as a critical enabler for digital transformation in warehouse operations, creating a foundation for future innovations in automation and artificial intelligence.

As SAP continues to enhance its Extended Warehouse Management capabilities and the Digital Vehicle Suite evolves, we anticipate even greater convergence between license plate management and emerging technologies such as machine learning for predictive put-away optimization, advanced analytics for labor management, and IoT integration for predictive quality assurance. For automotive suppliers committed to operational excellence, investing in advanced license plate management capabilities today creates a competitive advantage that will only strengthen as the industry continues its digital transformation journey.

At Mygo Consulting, our team of specialized SAP experts continues to partner with leading tier-one automotive suppliers to implement these transformative technologies, driving measurable improvements in warehouse efficiency, traceability, and overall supply chain resilience. As the industry evolves, we remain committed to advancing the application of license plate management and related technologies to address the unique challenges of automotive supply chains.

.png)

From my seat – inside deals, renewals, and delivery conversations every week – the story from early 2025 to early 2026 is simple: last year’s...

5 min read

11 min read

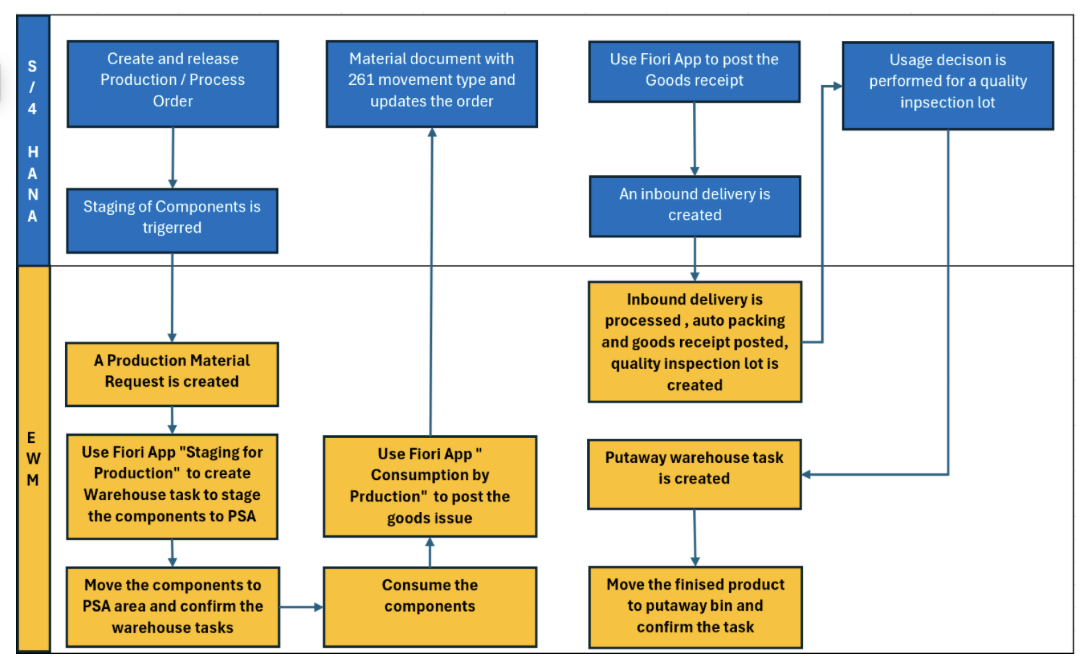

EWM-PP integration and various consumption options in S/4HANA with SAP Public/ Private Cloud / On-Premises

5 min read